WSRC-MS-2002-00902

Fifty

Years of Transuranic Waste at Savannah River Site

(From production to cleanup)

A.

Gibbs

Westinghouse Savannah River Company

Aiken, SC 29808

Three years into the Cold War, in 1950, President Truman asked the E. I. du Pont de Nemours Company to build and operate a plant to produce materials for nuclear weapons. The design and construction several years earlier of the Hanford Works in Washington state had given the planners of this new mission a good idea of what would be required: a large land area with a ready supply of water for the production of heavy water and cooling for the reactors, good transportation, a population sufficient to supply workers, and distance from major population centers.

After considering sites across the United States, the Atomic Energy Commission chose a location on the Savannah River near the towns of Augusta, Ga., and Aiken, S.C. The site had the necessary water supply, was in a semi-arid region with a heavy clay soil that would be acceptable for waste storage for a relatively long period of time, was sparsely populated, and had a good train transportation network.

No task such as this can be accomplished without heartache—and the establishment of the Savannah River Plant (SRP) was no exception. Entire towns and farms had to be relocated to acquire the needed space of about 300 square miles. While the approximately 1,500 families were compensated for their land and even family graves were moved, the dislocation ruptured the ties of generations. Production activities at Savannah River provided employment for many of the displaced residents. The same production activities generated waste, which will keep the displaced residents’ descendants employed for years in decommissioning, demolition, surveillance, containment, and shipping activities.

The original production mission at SRP was plutonium. The mission was later enlarged to include production of tritium for hydrogen bombs, plutonium-238 for space applications, and other isotopes, such as californium-252, which were of interest for medical and other research.

These production activities required five nuclear reactors that used heavy water—water enriched with deuterium—as their coolant and moderator, two aqueous separations facilities to separate the plutonium from the uranium targets, a solid/gas separation facility to separate the tritium from the lithium targets, a fabrication plant for the production of the targets, a production area for heavy water, and miscellaneous support facilities such as laboratories, power stations, shops, and a waste disposal area.

At the end of the Cold War in 1989, the Savannah River Plant became the Savannah River Site (SRS) under a new contractor: Westinghouse Electric Company. Waste handling became a larger part of the mission with the startup of the Defense Waste Processing Facility (DWPF) in 1992. This facility takes the high-activity liquid wastes containing actinides generated over the years at SRS and turns them into glass encased in stainless steel cylinders. The immobilized waste is currently stored at Savannah River in underground silos and is awaiting a final repository site.

The solid wastes have been disposed of or stored at a central point in the site that is more than five miles from any plant boundary. The "burial ground" is on a high point that has a clay soil which retards the migration of radionuclides (with the exception of tritium) to the groundwater and offsite areas. The original seventy-six acres used from 1953 to 1972 will be permanently sealed in 2003 under a Resource Conservation and Recovery Act (RCRA)-approved closure cap. Additional acreage currently is used for disposal of low-level waste and concrete pads have been built in the acreage for storage of transuranic (TRU) waste drums.

TRU waste is stored under cover among buried waste at SRS in the center of the site.

TRU waste is defined as waste containing any of the radioactive nuclides above uranium in the periodic table that have a half-life more than twenty years in a concentration greater than 100 nanocuries per gram of waste. Because of the potential hazards to the environment, SRS has always separated waste containing or suspected of containing these radionuclides. While some of this waste has been buried and will be under the RCRA closure cap, the vast majority has been stored in drums on pads for future retrieval. The pads are covered with giant tent-like enclosures called RUBs (after the manufacturer) to protect the drums from rain.

TRU waste storage under RUB enclosure.

Until recently, the quantity of waste containing transuranic nuclides was relatively low because the plutonium in the waste was recycled to meet production schedules. Nuclides above plutonium were even more valuable and were also recycled, consequently producing little waste. Most of the waste at SRS contains either plutonium-238, plutonium-239, neptunium-237, or americium-241.

Because there were no field measurement instruments capable of determining low concentrations of transuranic radionuclides in 1972, all waste originating in operations areas containing transuranic nuclides was stored. SRS now finds that many of the containers do not meet the definition of TRU waste because they have concentrations of less than 100 nanocuries per gram. These containers should be disposed of as low-level waste, but they suffer from another consequence of too much conservatism—they are noted as containing "solvent" rags.

The "solvent rag" designation was applied indiscriminately to all containers in storage when there was an interpretation by Region 4 EPA in 1990 that any waste containing materials that had been exposed to solvents was hazardous. The time needed to make the case for not applying the designation exceeded the budget available and the probable consequences were far in the future, so the designation was made.

In the mid-1990s, SRS began a vent and purge program to insert filter vents on all of its unvented stored drums. At the same time, programs for sorting the post-1990 drums into low-level and TRU waste, and retrieval of drums stored in earthen berms, began. These drums of waste are now being analyzed and characterized for shipment to the Waste Isolation Pilot Plant (WIPP) near Carlsbad, N.M. Shipment to WIPP requires an Acceptable Knowledge (AK) document detailing how the waste was generated and then confirmation of the AK.

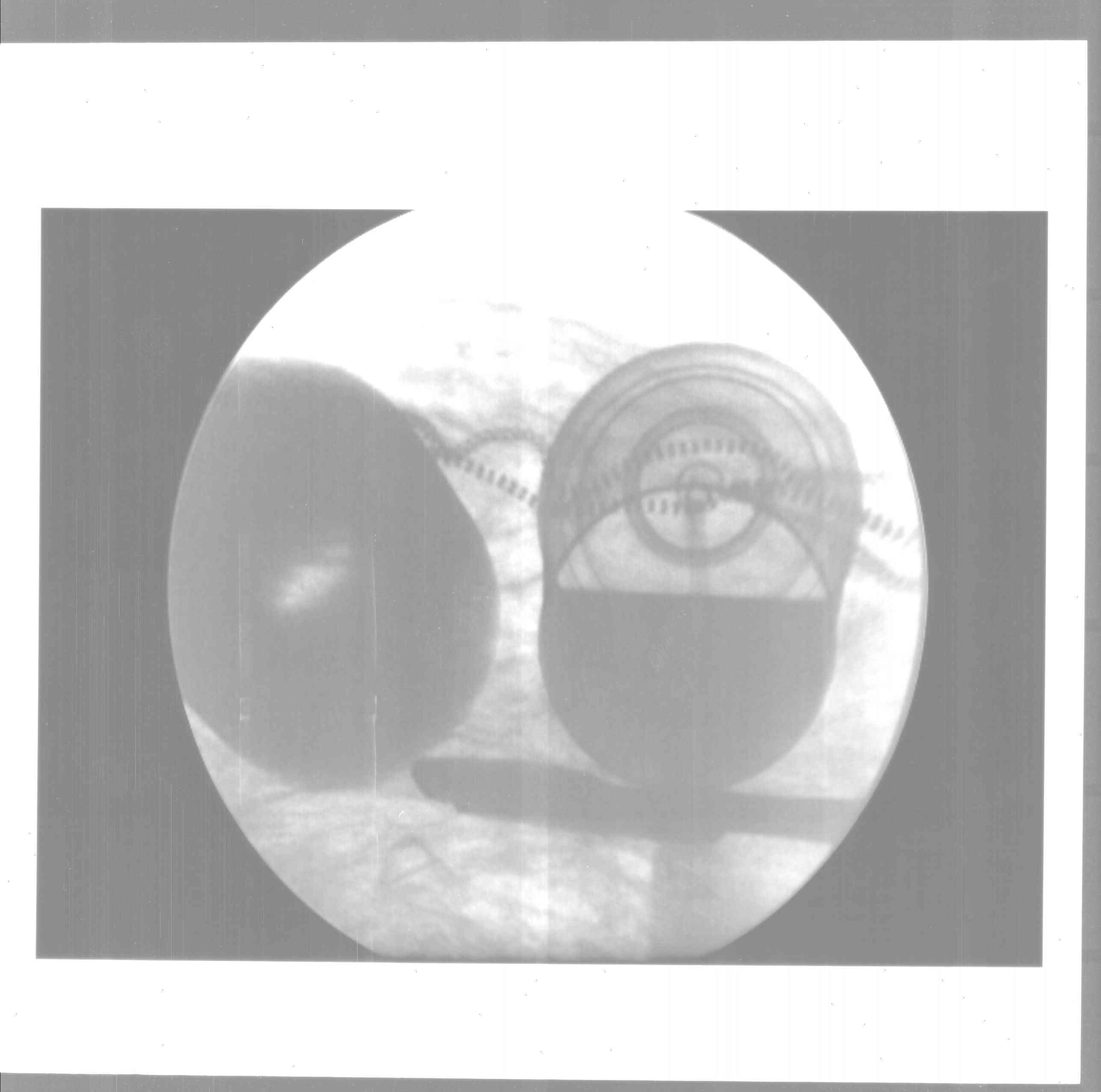

Several technologies are used to confirm the makeup of waste. Real-time radiography or digital radiography is performed on the containers to ensure that prohibited items such as aerosol cans or liquids are not present. After weighing, a nondestructive assay (NDA) is done to quantify the TRU waste present and its radionuclide distribution. A gas analysis is also done on a sample of the head-space gas in each container to quantify and identify the gases to ensure that shipment in the sealed transportation container (TRUPACT-II) will not incur any risks.

Radiograph

of TRU waste container showing roll of tape, protective clothing (zipper),

aerosol can containing liquid, and pair of scissors. This container

was rejected for shipment to WIPP.

Researchers at SRS use a passive-active neutron (PAN) instrument developed at Los Alamos in the mid-1980s for NDA analyses of low quantities of TRU waste. The PAN at SRS has a sensitivity of approximately 20 nanocuries per gram for 20 kilogram of waste.

In passive mode, the instrument detects spontaneous neutrons and neutrons produced by alpha interaction with fluoride or other light elements. In active mode, the instrument uses a neutron generator that emits 14-million-electron-volt neutrons to produce coincident neutrons from fissionable material such as plutonium-239. The active mode is the most sensitive and also is subject to the most interferences. The radioactive nuclide in the Acceptable Knowledge is confirmed by gamma analysis.

Generator which produces 14 MeV neutrons to bombard waste to determine TRU content.

Savannah River’s PAN response is reliable only up to approximately 1 gram of plutonium-239. Above this quantity, clumping, self-shielding, and other factors make the results questionable.

For amounts above 1 gram, SRS uses a segmented gamma scanner (SGS) to quantify plutonium-239 and obtain a distribution of the other TRU radionuclides. Reference materials used for checking the performance of the NDA instruments were made by Los Alamos and distributed through the WIPP program.

The gas analyses are done by puncturing the carbon filter vents drawing off the head-space gases into evacuated containers. The container contents are then analyzed using gas chromatography-mass spectrometry. Reference materials are also distributed by WIPP for these analyses.

Subsequent testing of the drums may include visual examination of the contents to check the x-ray analyses. This is done in a glovebox where all the waste is dumped and sorted by hand while video cameras film the operation.

Savannah River’s waste-certification

analyses recently were taken over by the Carlsbad Central Certification

Project (CCP) and the work contracted out to accelerate the TRU waste

shipments from SRS to WIPP. Speeding up the shipments will allow waste

from the Mound Laboratory in Ohio to be brought to SRS for interim storage,

which in turn will accelerate the closure date of the Mound site. The

contractors are using the same techniques as SRS did, but with newer models

of equipment.

Transportation

on the Savannah River Site

Empty fields are now filled with pine trees planted by U. S. Forestry Service.

First shipment of TRU waste from SRS to WIPP leaves site in 1991.

What a difference 50 years make. In 1951, houses that had been people’s homes for generations had to be moved to make room for the Savannah River Plant, which was needed at the time to produce nuclear material for weapons. By 2000, that capability had been shut down for ten years. The cleanup of the site involves shipping waste in special containers known as TRUPACT-IIs to the Waste Isolation Pilot Plant (WIPP) in New Mexico. Each shipment—including certification and licensing of the TRUPACT-IIs, certification costs for the waste, training for waste certification personnel and drivers, and security—costs more than moving all the homes on SRS property did in 1951.

Information for the article was taken from "History of Du Pont at the Savannah River Plant", W. P. Bebbington, E. I. Du Pont De Nemours and Company, Wilmington, DL, 1990.