WSRC-MS-2002-00431

Insitu Cleanable Alternative HEPA Filter Media

D. J. Adamson and D. B. Burns

Westinghouse Savannah River Company

Aiken, SC 29808

M. T. Terry

Los Alamos National Laboratory

Richland, WA 99352

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

This report has been reproduced directly from the best available copy.

Available for sale to the public, in paper, from: U.S. Department of Commerce, National Technical Information Service, 5285 Port Royal Road, Springfield, VA 22161, phone: (800) 553-6847, fax: (703) 605-6900, email: orders@ntis.fedworld.gov online ordering: http://www.ntis.gov/support/index.html

Available electronically at http://www.osti.gov/bridge

Available for a processing fee to U.S. Department

of Energy and its contractors, in paper, from: U.S. Department of Energy, Office

of Scientific and Technical Information, P.O. Box 62, Oak Ridge, TN 37831-0062,

phone: (865 ) 576-8401, fax: (865) 576-5728, email: reports@adonis.osti.gov

Abstract

Two types of filter media, sintered nickel metal and ceramic monolith membrane, are being investigated as in situ regenerable/cleanable high efficiency particulate air (HEPA) filters. Particle retention testing was conducted on the filters at the Oak Ridge Filter Test Facility to ensure HEPA efficiency, > 99.97%. During simulant testing, The filters were challenged using non-radioactive simulated high-level waste materials and atmospheric dust; materials that cause filter pluggage in the field. After plugging the filters they were cleaned in situ using an aqueous solution. This innovative approach of the in situ regenerative filtration system may be a significant improvement upon the shortfalls of conventional disposable HEPA filters.

Background

Conventional disposable glass-fiber HEPA filters are used throughout the Department of Energy (DOE) complex in various process systems. The filters must exhibit a particle removal efficiency of 99.97% when challenged by thermally generated di-octyl phthalate (DOP) aerosol with a diameter of 0.3 microns. The pleated glass fiber HEPA filter media has approximately 22.3 m2 of surface area and is typically contained in a 0.6m x 0.6m x 0.3m housing and exhibits a 25 mm of water column (wc) differential pressure across the filter media when clean. A conventional HEPA filter remains in service until the filter media reaches a predetermined maximum pressure drop (approximately 125 mm) or a high source term due to radioactive buildup, and then the filter is replaced.

These filters require routine removal, replacement, and disposal. This process is not only expensive, but also subjects personnel to radiation exposure and adds to an ever-growing waste disposal problem. The conventional HEPA filters also have safety concerns in the areas of filter media strength, water damage, and operation in environments with elevated temperatures. The Defense Nuclear Facility Safety Board (DNFSB) issued a report titled "HEPA Filters used in the Department of Energy Hazardous Facilities", DNFSB/TECH-23.1 This technical report documents these and other concerns pertaining to conventional HEPA filters.

To address most of the safety issues associated with the glass fiber filters, the DOE has recently been investing in the development of robust HEPA filters that can be regenerated or cleaned in situ. Previous research has been conducted at other US DOE sites, such as Lawrence Livermore National Laboratory (LLNL) and Oak Ridge National Laboratory, to develop in situ cleanable or regenerative HEPA filters with high media strength. W. Bergman, et al conducted research on various filter media, such as steel fibers, ceramic, and sintered metal, using reverse air pulse as the in situ cleaning method.2 The results of these investigations indicate that commercially available filter media could be applied to the development of an in situ cleanable (using reverse air pulse) HEPA filter system that would meet the performance criteria established for a conventional HEPA filter media.

Introduction

Under funding from the DOE Tanks Focus Area, the National Energy Technology Laboratory (NETL) issued a "Request for Proposals" late in 1999 to identify vendors conducting research in the area of in situ cleanable/regenerative filters or vendors interested in pursuing such technology. A technical evaluation was conducted on the proposals. Based on the proposals reviewed, CeraMem Corporation (Waltham, Massachusetts) and Mott Corporation (Farmington, Connecticut) were selected to support this research program. In the initial phase of the program, CeraMem and Mott developed small test units (lab scale filters) that demonstrated HEPA filter particle retention performance and ability to be regenerated by cleaning in situ using an aqueous solution. CeraMem provided a ceramic monolith filter and Mott provided a sintered metal filter. Proof of principle for an in situ cleanable HEPA filter was a success with the lab scale filters.3, 4 An American Society of Mechanical Engineers (ASME) Peer Review of the program was completed. The Peer Review Panel was complementary of the technology and the research.5, 6 Testing is ongoing with ceramic and sintered metal full-scale single elements.

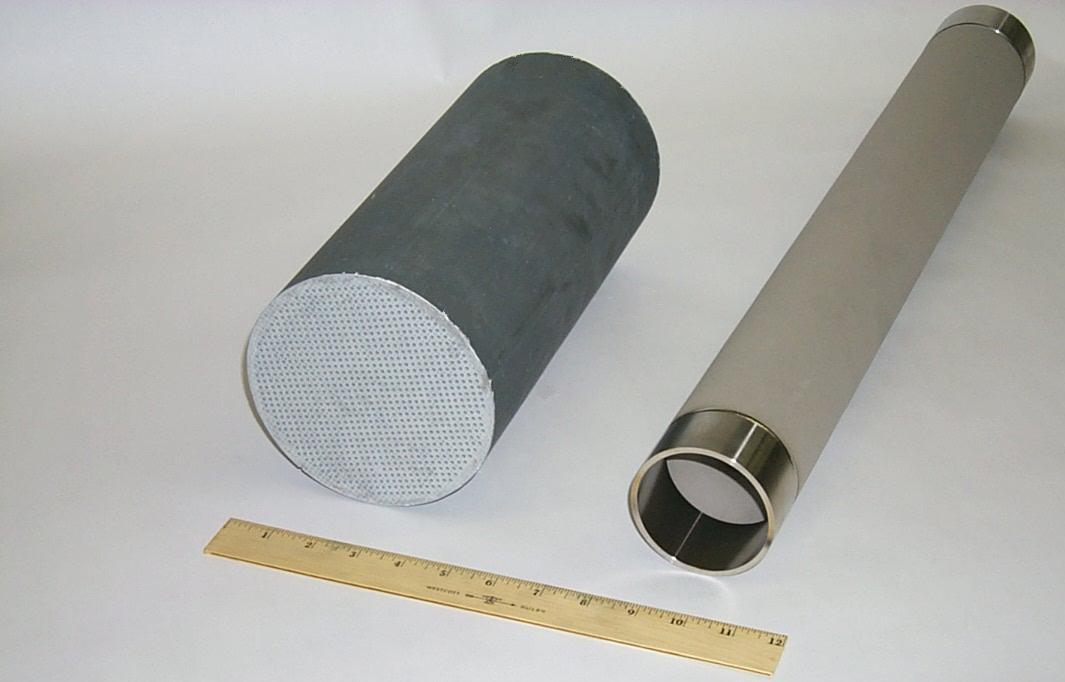

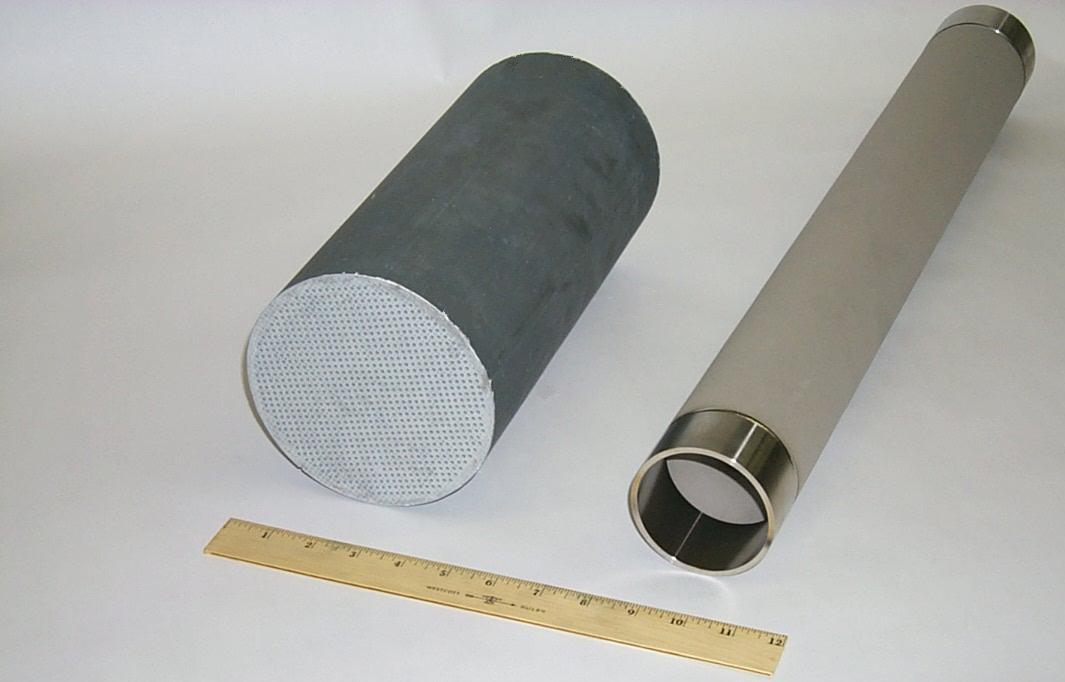

Figure 1 depicts the full-scale ceramic (left) and sintered metal (right) filter elements.

Figure 1. Full-size Ceramic and Sintered Metal Filters

The ceramic filter media is a "dead-end" monolith filter. The passageway ends are plugged with ceramic cement in an "alternate, checkerboard pattern" as shown in figure 2.

Figure 2. Airflow Path Ceramic Filter Media

The dirty air with particulate matter enters the filter media and the gas flow is constrained to pass through the monolith walls separating inlet and outlet passageways. The membrane coating covers the passageway walls, and the entrained particles are filtered from the air onto the surface of the microporous membrane. The clean air flows down the outlet passageways and is exhausted from the filter. Below are the characteristics of the "full-scale" ceramic monolith filters tested in this phase of the program:

Figure 3 is a photomicrograph of a cross-section view of the silicon carbide (SiC) monolith pore structure with a membrane surface coating, with a pore size between 0.2 – 0.5 m m. This ceramic membrane provides a relative low-pressure drop (for a robust media) while obtaining HEPA filter retention efficiency.

Figure 3. Cross-sectional Membrane/Monolith Structure

Below are the characteristics of the "full-scale" sintered metal filters tested in this phase of the program:

A photomicrograph magnified 1000 times of the sintered Nickel media is shown in figure 4. The media has a pore size between 0.2 – 0.5 m m and provides high particle retention efficiencies but has a small surface area in a given geometry resulting in a higher pressure drop than the ceramic filter for given airflow.

Figure 4. Micrograph of Sintered Ni Media

Due to the finer metal powder and resulting porous media structure, Nickel 200 media has much higher particle collection efficiency than other sintered metals. The pressure drop of the Ni media is about half that of stainless steel media. Nickel 200 is >99% pure Ni, which has excellent corrosion properties. In many cases nickel is more corrosion resistant than 316L stainless steel. The Ni media is a very good corrosion resistant material for a variety of corrosive environments. Nickel should out perform 316LSS in most applications such as when exposed to normal atmosphere, water, hydrochloric acid and other chlorides, organic acids like acetic acid, caustic soda and other alkalies (except ammonium hydroxide), ammonia, and salt water. Nickel 200 is not good for hot gas service, where sulfur is present.

Results and Discussion

Particle Retention Testing at ORNL

Particle retention efficiency testing was conducted on the full-scale filter elements at the Oak Ridge Filter Test Facility (FTF). Air Techniques International (ATI) operates the Department of Energy facility under contract. ATI modified their FTF test equipment to conduct efficiency tests on the alternative full-scale filter elements. DOP, which is an organic compound, is a standard in the HEPA filter industry for conducting particle retention test was used in the challenge tests.

The vendors were asked to optimize the particle retention vs. the dP and supply approximately 30 filter elements. A total of 28 ceramic and 38 sintered metal full-scale filter elements were supplied to the FTF. Table 1 shows the results for the ceramic filter. A total of 9 out of 26 filters tested passed the particle retention test with greater than 99.97% efficiency. The high number of filters that failed is not seen as a negative, but indicates that the vendor could vary manufacturing techniques to optimize the dP vs. retention that was requested. Each ceramic filter was tested at two different flows, 3.54 m3/min and 0.71 m3/min. Testing results proved that full-scale ceramic filter elements with HEPA retention could be manufactured. Also varying manufacturing techniques provided critical manufacturing data to the vendor for manufacturing pre-filters for various application across the DOE complex and commercially.

Thirty-four of the 35 sintered metal full-scale filters tested, passed the particle retention test with greater than 99.97% efficiency. The sintered metal filters tested have a very high retention. Due to the manufacturing procedures for manufacturing sintered filters, the vendor found it very difficult to optimize dP vs. particle retention. 68% of the filters tested had 99.999% particle retention efficiency, which is over a magnitude higher in filtration than is required for a HEPA filter.

Simulant Testing at SRTC

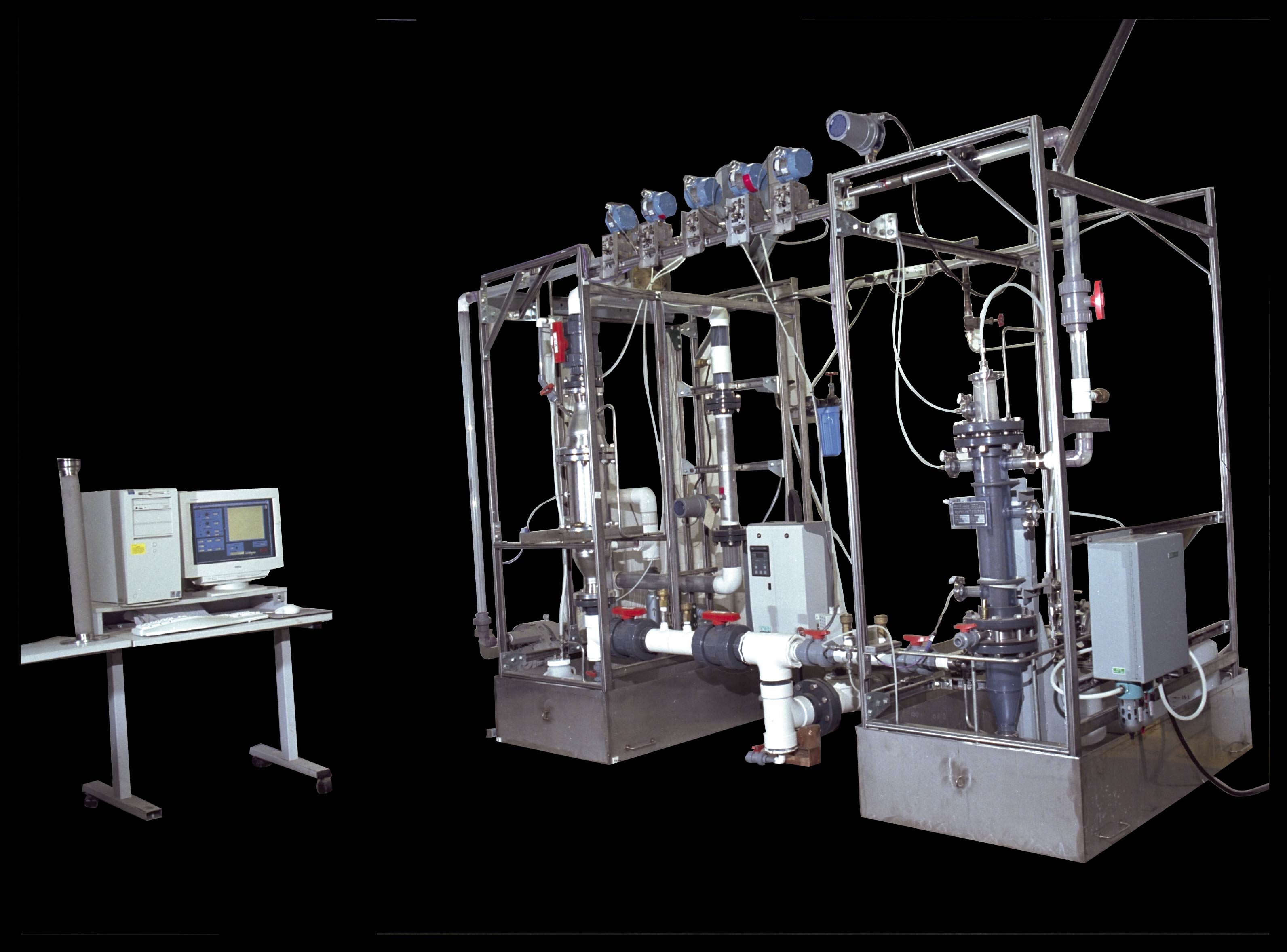

A HEPA filter test apparatus (HFTA) was designed and constructed to test the single element full-scale filters. The HFTA was designed to simulate the conditions that challenge conventional filters on the 3.8 million liters high-level radioactive waste (HLW) tanks at SRS. Figure 5 is a photo of the HFTA constructed at SRTC.

Figure 5. Full-scale Single Element Test Apparatus

The filters were challenged by entrained particulates of simulated HLW and atmospheric dust. These materials, neglecting the radioactive constituents, are believed to be responsible for plugging the existing HEPA filters in the HLW tanks. Three materials are used; simulated HLW sludge, salt and atmospheric dust. Only one material was used at a time to challenge the filters.

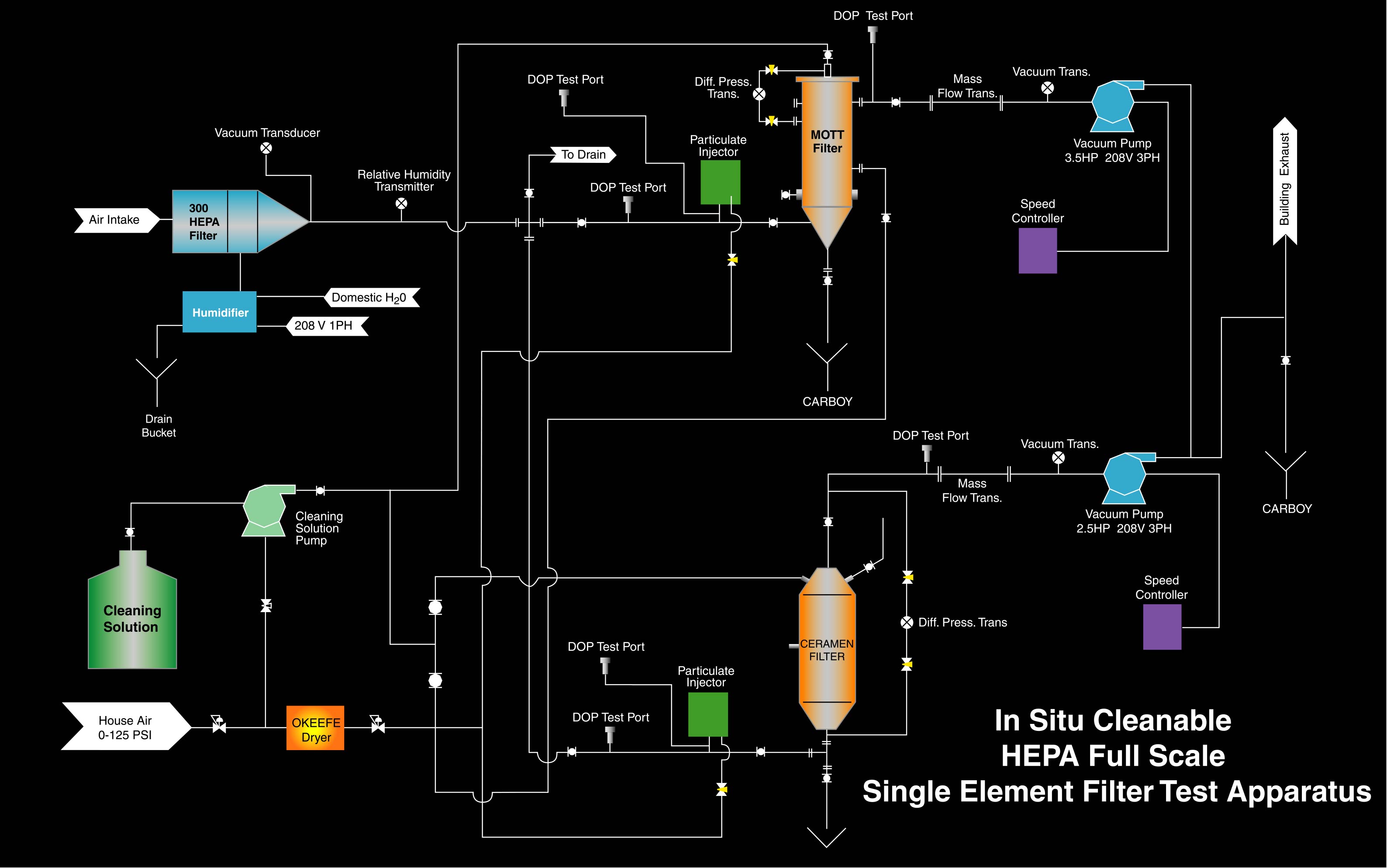

The test was designed for approximately 3.7 m3/min of filtered air to flow into the system. The air was split with approximately 2.8 m3/min flowing through the ceramic filter and 0.85 m3/min through the sintered metal filters. A separate blower or vacuum pump was used to pull the air across each filter as depicted figure 6. DOP test connectors were designed into the HFTA to conduct in-place leak tests on the filter media.

Figure 6. Schematic of Test Apparatus

The HFTA was designed such that one filter could be cleaned while the other remained online. The system operated continuously (24 hours a day, 7 days a week) until the dP across the filter(s) increased by 20% or more due to particulate matter build-up on the surface of the filter. The airflow across the filters was constant, 2.83 m3/min for the ceramic filter and 0.85 m3/min for the metal filter. Once a filter became soiled from filtering simulated HLW particles from the air stream, it was cleaned in situ using de-ionized (DI) water or an aqueous solution. In situ cleaning was conducted on the sintered metal filter via spraying the inside (dirty side) of the filter with a dilute oxalic acid then rinsed with DI water. The ceramic filter was cleaned in situ by backflushing a dilute nitric acid solution into the dirty side of the filter and rinsed with DI water. A purge of dry compressed air was used to back-flow through the filter to aid in removing water droplets from the media. After the in situ wash cycle, the filter(s) was returned to operation.

Figure 7 is an aggressive loading and cleaning curve, created from data that was logged every 15 minutes using an data acquisition system. The ceramic filter was challenged with sludge particles and cleaned insitu four different cycles.

Figure 7. Loading/Cleaning Data (2.8 m3/min)

In this heavy loading test, the filter was cleaned only with DI water. As shown in the figure, the filter regenerated well using only water. However, there was a small pressure drop that was not recovered with each cleaning cycle when using only water. There is a point where a cleaning solution is need to reduce surface tension and dissolve lodged particles to return the filter to a clean filter status.

The full-scale ceramic and sintered metal test filters that were subjected to approximately ten loading of simulant particles and insitu cleanings, were returned to the Oak Ridge FTF for post particle retention test. The results were positive that there was little or no change in the retention capability of both the ceramic and sintered metal filters after the many plugging/ in situ cleaning cycles. This indicates that the filter media is not deteriorating when undergoing repeated plugging and cleaning cycles.

There are potentially many applications of these alternative media, such as the prevention of alpha and beta buildup emitters on filters in process. An unknown quantity of radionuclides on a filter media in process system is a concern of waste management groups, particularly in the case of a catastrophic HEPA filter failure where a release to the environment can occur. The in situ cleanable filter could also be used in other applications such as to permit recovery of materials that may collect on HEPA filters during normal process operations and in the area of bio-terrorism research. Materials used by terrorist such as anthrax can remain in a dormant state for many years. Facility conducting research with such materials, would have the option to destroy the organisms in the HEPA filters using high temperatures or antiseptic solutions before the filters are manually handled and/or sent to solid waste.

During wild fires, heavy smoke and smoke borne particulates may plug the alternative filter, but test results indicate that the plugged condition will not cause filter failure and/or breakthrough.

Full-scale System Hot Deployment

A full-scale Alternative Filtration System is planned for construction with the hot (radioactive) demonstration of the system being conducted at SRS on a HLW Tank. Before the hot deployment on a HLW tank, the full-scale system will undergo cold testing at SRTC. The sintered metal filter-housing layout being considered for the full-scale demonstration will consist of approximately twenty-four (24) full-scale elements. The filter elements and filter housing will be an all welded construction, meaning that there will be no seal or gaskets to contend with. As currently conceived, air will be drawn into the open bottom of each filter element and be pulled through the filter wall by vacuum applied to the clean plenum. The dirty side of the filter will be the inter diameter of the cylindrical element. The multiple vertical tubes will be welded into an arrangement resembling a tube and sheet heat exchanger. After the filter becomes plugged with particulate or when the radioactivity from the accumulated particulate approaches area limits, the in situ cleaning system will be initiated. Each element will have a separate spray nozzle(s) and the filter will be cleaned via spraying the inlet side of the filter with an aqueous solution. For the full-scale demonstration of the ceramic media, the housing will consist of approximately seven (7) full-scale filter elements. The current full-scale design requires seals to install the elements in the housing properly. The dirty air will be drawn into the bottom end of the housing and clean air will exit through the top of housing. The elements are cleaned in situ via back flushing an aqueous solution through the media. The spent cleaning solution will be deposited in the HLW tank, thus not creating an additional waste stream.

Conclusion

Ceramic and sintered metal media holds great promise as an in situ cleanable/regenerative HEPA filters for many application across the DOE complex and commercially. Testing of the full-scale single element has shown that both ceramic and sintered metal media could be suitable as an alternative HEPA filter media. Data from particle retention testing at the Oak Ridge Filter Test Facility shows that the alternative filters are capable of particle retention greater than 99.97%. Ongoing HLW simulated testing on the full-scale filter elements indicate that the filters regenerate well in situ with a potential for 15 year plus life under actual field conditions of the HLW tanks. In addition to eliminating the costs associated with disposing of and replacing disposable filters, these robust/strong filter media also reduce the potential of a catastrophic HEPA filter failure due to rupture or fire of the media.

References